advantages of outsourcing

your production process

Designing, preparation and manufacturing of new products is demanding and time-consuming. That’s why more and more companies decide to outsource their manufacturing process to gain a competitive edge in the market. This allows them to save time and cut down production costs.

why eubioco?

We offer a full range of contract manufacturing services, from first concept drafts to introducing the product to the market.

We manufacture both large and small batches. Our quality control procedures remain equally strict on all stages of the production process.

We approach all projects individually, carefully preparing for each stage of the production process. After the initial analysis of our Client’s needs and expectations, we assemble a team of specialists from various departments to work on the project. This way, our Clients receive expert support and guidance that closely matches the nature of each project.

every project tailored to your needs

we support our Clients at all stages of the production process – from manufacturing to sales

- analysis

market and category - brand strategy

marketing mix in line with the strategy - formulation

innovations and unique selling points - packaging

promotional materials and design - registration

documentation and registration - manufacturing

timing and logistics - training

pharmacists and patients - marketing

POS and MIX marketing - sales

knowledge testing

we offer various production options, including:

liquid products:

- gels, ointments, ointment bases, creams

- syrups, emulsions, shampoos, drops

- suppositories, pessaries

dry products:

- tablets: round and oblong, uncoated and coated (in bulk; 6mm; 8mm; 9x5mm; 11mm; 12mm; 19x7mm, 19×9.5mm )

- hard capsules (0, 00, 2)

- powders: sachets, in bulk

manufacturing services:

- packaging – aluminium, laminate and plastic tubes

- packaging liquids in PE/PP bottles or containers

- bottling tablets and capsules

- PVC, PVDC/ALU blister packaging (tablets: a’ 5, a’ 10, a’ 15, a’ 20; capsules: a’ 10, a’ 15 a’ 20)

- one/two-sided labelling of individual and bulk packets

- packaging in individual and bulk boxes

- repackaging

areas of cooperation with Clients

in contract manufacturing:

marketing

We offer wide-ranging consultancy services regarding every field of marketing for the products we manufacture. We swiftly respond to the changing market environment and support our Clients in designing full marketing and branding concepts for their products. We cover all areas of the marketing process, from the first idea, brand and vision, all the way to establishing unique selling points, value for patients and necessary communication tools. As part of those services, we also provide packaging designs, in cooperation with an experienced and trusted branding agency. We prepare descriptions and marketing content in accordance with all legislation and applicable regulations, and advertising concept using the latest trends and tools.

laboratories

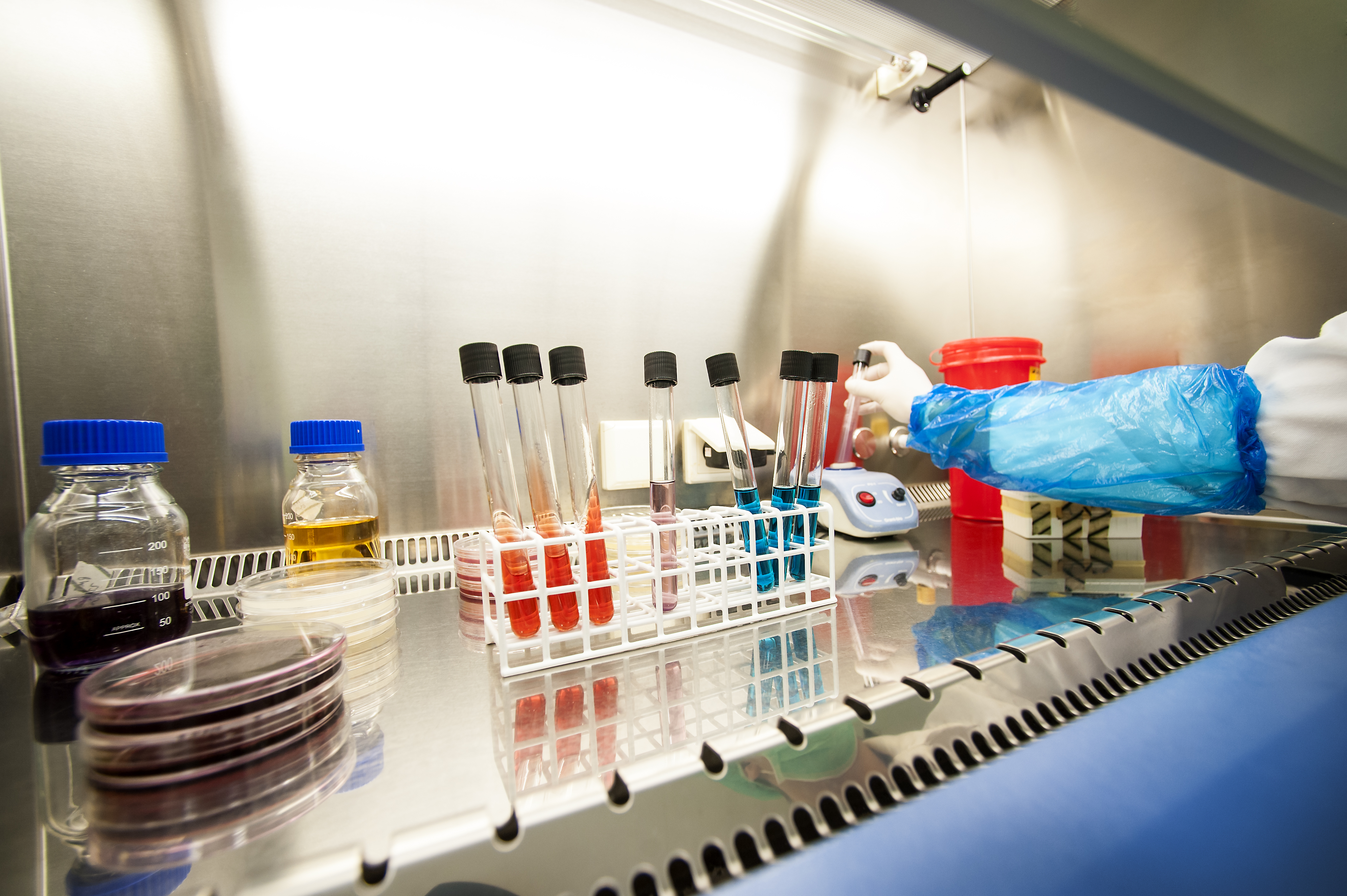

In our in-house laboratories, we analyse and verify formulations prepared by our technicians. Both our in-house labs and external ones we work with through trusted outsourced companies, guarantee the durability and safety of all products we manufacture.

R&D

We offer a full scope of work on their products (dietary supplements, medical and medicinal products) from initial concept to implementation, including:

- preparation of the product formulation

- choosing high-quality components and trusted suppliers

- technology development

- product analysis, including stability testing (long-term, accelerated, indirect)

- process validation

- full system documentation, appropriate for the legal status of each product

Our Development Department, together with other departments within the company (Production, Quality Control, Quality Assurance System) and various scientific bodies, designs and commercialises innovative new products. Our portfolio includes numerous solutions that allow us to meet our Clients’ expectations and actively contribute to creating new market trends.

production

Our production is a multi-stage process, carried out with the use of advanced personalised computer systems, such as ARIEL and EPIONE. We are gradually expanding our equipment base, raise our employees’ qualifications and implement the latest technologies, which leads to timely deliveries, low cost of production and faster processing and delivery of ongoing orders.

quality control

We ensure there are quality control checks carried out on all stages of the production process – from the choice of components and packagings to testing finished products before releasing them into the market. Our Quality Control Department works in accordance with the global Good Manufacture Practice standards and the European Pharmacopoeia, ensuring control over the quality of all medications, dietary supplements, cosmetics and medical products we manufacture. The Quality Control Department includes chemical and microbiological laboratories, equipped with state-of-the-art, advanced testing devices that allow maintaining adequate parameters and eliminating potential dangers during the product’s lifecycle. We also register our supplements at the GIS platform and our cosmetics at the CPNP website, in accordance with the EU legislation. Our Quality Control Department also monitors any legal changes regarding existing formulas and manages the entire process regarding any necessary documentation.

registration and documentation

In order to provide a comprehensive support service for the development of the product with a specific legal status, we offer our Clients a wide range of services regarding registration of dietary supplements, medical and medicinal products.

logistics

We design tailor-made solutions for managing the supply chain. Our company provides support for warehousing and transport, movement registration and product tracing throughout the entire supply chain, as well as product identification on every stage of the service provided. We work in accordance with all necessary procedures and IT solutions required by the market and the legal framework. Eubioco works with many trusted transport companies, which means we can ensure optimal transport conditions, tailored to our Clients’ needs and following the pharmaceutical law, Good Distribution Practice, and Good Manufacturing Practice.